Integrating digital technologies into manufacturing (Industry 4.0) is a vital necessity for Danish SMEs to remain competitive in today’s market. A significant hurdle for SMEs in leveraging Industry 4.0 is the high capital cost of replacing functioning classic machinery (i.e., manually controlled machine tools) with newer digital counterparts. This project aims at addressing this challenge by augmenting classic machinery with existing, low-cost, off-the-shelf, microcontrollers & sensors for aiding data-driven design & production decision-making.

This project focuses on creating computer-supported innovation and creativity tools for aiding sustainable product/process re-design in the manufacturing industry. As a first step, we are conducting interview-based studies that will benchmark existing innovation practices prevalent in industries, including management-led initiatives and bottom-up innovation for sustainability.

Industry and Research Collaborators

Key Publications

The life cycle environmental impact for many products is largely dictated by their use phase resource consumption. However, there is limited information available from these stages to guide product and process design. This project focuses and addressing this gap through digital tools that , (1) enable understanding users’ consumption and disposal practices, and (2) inform users about contextual best practices from a sustainability perspective.

Industry and Research Collaborators

Key Publications

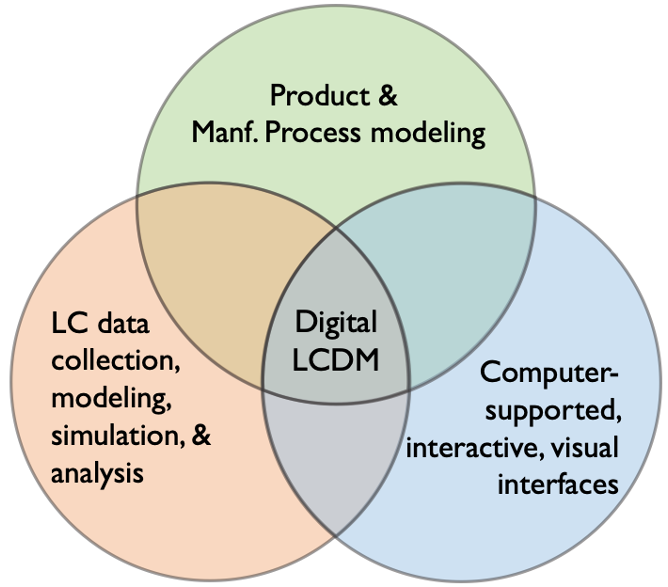

This project focuses on creating visual analytics tools sustainable design & manufacturing that combine the abilities of computer-based tools to gather, process, and summarize data along with the ability of human-experts to guide analyses through domain knowledge and data-driven insight.

Industry and Research Collaborators

Key Publications

Instruction approaches based on design critique, guided discovery, and experiential learning for incorporating sustainability assessment into graduate and undergraduate engineering courses.

Industry and Research Collaborators

Key Publications